ASME Gas Filter Separator

1. The treatment accuracy of solid particles can reach 0.5 m, and the filtration efficiency reaches 99.99%.

2. The removal rate of the droplets above 1 m is over 99%.

3. The pressure drop of the equipment under normal working conditions is less than 10kPa.

4. The filter element is compressed by the PEM material multi-layer structure, which has the advantages of strong anti-corrosion ability, complete incineration and no plastic residue after use.

5. Two kinds of structural forms are used for selection, one is the blade catcher, the other is the silk net trap, which is selected according to the medium condition.

6. Use the quick opening closure for easy replacement of filter and maintenance equipment.

7. Intelligent differential pressure transmitter can display the operation of the filter element on site, and can realize remote transmission and alarm function.

8.Execution standard:ASME, API, NACE.

- WS

- Shenyang,Liaoning,China

- within the required time

- supply qualified goods within required time

- Information

Main Filter Separator Type which we can design and fabricate | ●ASME THREE STATE FILTER SEPARATOR http://www.wsyqworld.com/product/asme-three-state-filter-separator |

| ●ASME GAS FILTER SEPARATOR | |

| ●ASME BASKET FILTER http://www.wsyqworld.com/product/asme-basket-filter | |

| ●ASME FILTER SEPARATOR SKID http://www.wsyqworld.com/product/asme-filter-separator-skid | |

| ●ASME FILTERING CYCLONE SEPARATOR http://www.wsyqworld.com/product/asme-filtering-cyclone-separator | |

| ●ASME AIR ELIMINATOR http://www.wsyqworld.com/product/asme-air-eliminator |

ASME Standard Nature Gas Separator

| ASME Gas Separator | |

Classify Gas Separator type through working medium | ASME Gas ,solid separator |

| ASME Gas,liquid separator | |

| ASME Gas Separator | |

Classify Gas Separator type through Installation Methods | Horizontal ASME Gas Separator |

| Vertical ASME Gas Separator | |

Breif Introduction

The natural gas filter/filter separator is used to intercept the solid particles and droplets in the gas through the filter medium, which can separate the fine particles,

dust and mist droplets in the gas.

High separation accuracy. It is widely used in gas gathering and transportation.

The natural gas filter separator is a three-stage filtration device that performs coarse filtration, semi-fine filtration, and fine filtration on the basis of centrifugal separation,

mesh flocculation, and cohesion interception.

It is a highly efficient purification of solid impurities and liquid impurities in gases Device.

High purification efficiency, large dust holding capacity, stable operation, low investment and operating costs, and easy installation and use.

Suitable for natural gas, city gas, mine gas, liquefied petroleum gas, air and other gases.

It is an indispensable purification equipment for the petrochemical, metallurgical and gas industries.

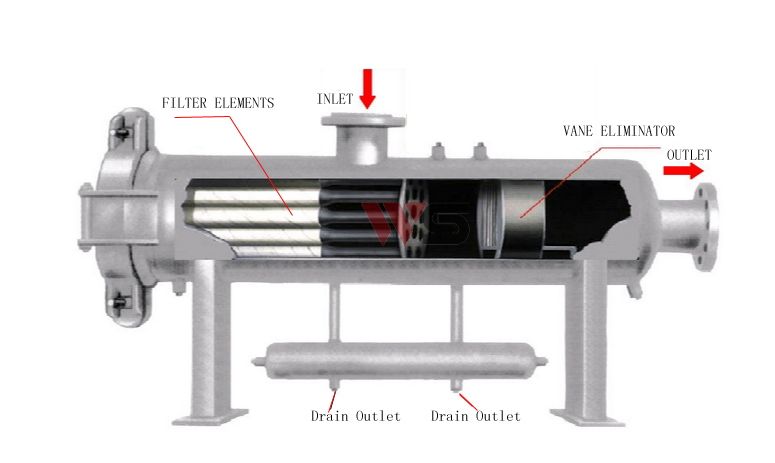

Working Principle

The natural gas filter is mainly composed of a cyclone separator, two-stage inertia demister pre-filtration and coagulation, a three-stage fine filter core agglomerate, and a drain valve. The natural gas entrained with liquid and solid particles enters the tangent direction from the intake pipe.After cyclone separation, larger droplets and solid particles are separated. Then, after passing through the secondary demister, the gas is further separated by gas, liquid and solid under inertial collision. Larger dust particles in the gas are filtered to protect the final fine filter element. The gas passes through a fine filter element (third-stage fine filtration) and solid particles with a particle size of more than 10 μm (or finer) are filtered out; Tiny liquid mists with a small particle size are collected on the fine filter element and aggregated into larger ones. The droplets, under gravity, settle to the bottom of the fine filter tube. The separated liquid is discharged from each sewage outlet, and the processed natural gas is output from the air outlet at the top of the filter. The device adopts the principle of mechanical separation, microfiber filtration and microporous medium condensation growth, and has a very high dust removal and filtration precision and desiccant capacity. |

Product features and technical indicators

1. The treatment accuracy of solid particles can reach 0.5 m, and the filtration efficiency reaches 99.99%.

2. The removal rate of the droplets above 1 m is over 99%.

3. The pressure drop of the equipment under normal working conditions is less than 10kPa.

4. The filter element is compressed by the PEM material multi-layer structure, which has the advantages of strong anti-corrosion ability,

complete incineration and no plastic residue after use.

5. Two kinds of structural forms are used for selection, one is the blade catcher, the other is the silk net trap, which is selected according to the medium condition.

6. Use the quick opening closure for easy replacement of filter and maintenance equipment.

7. Intelligent differential pressure transmitter can display the operation of the filter element on site, and can realize remote transmission and alarm function.

8.Execution standard:ASME, API, NACE.

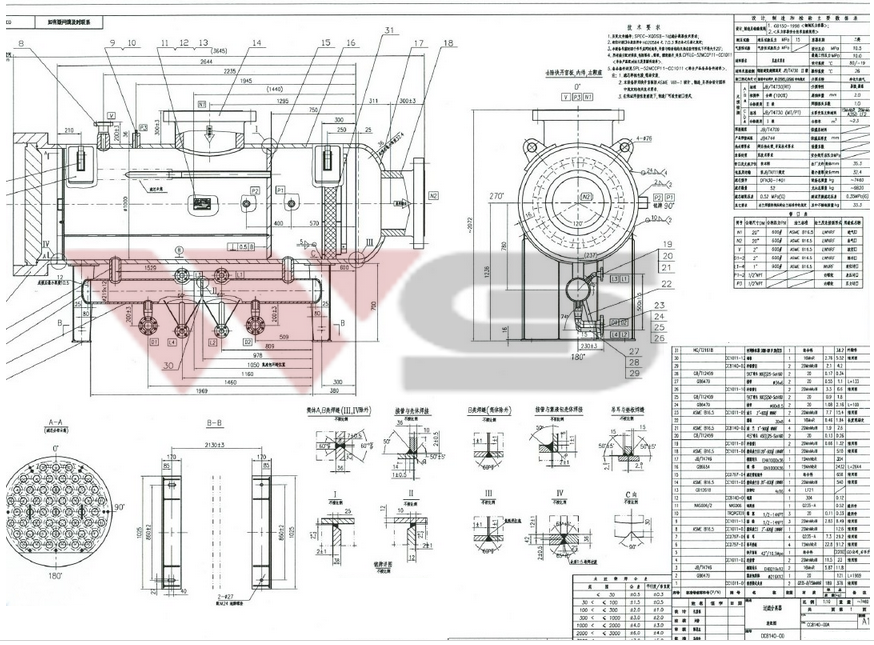

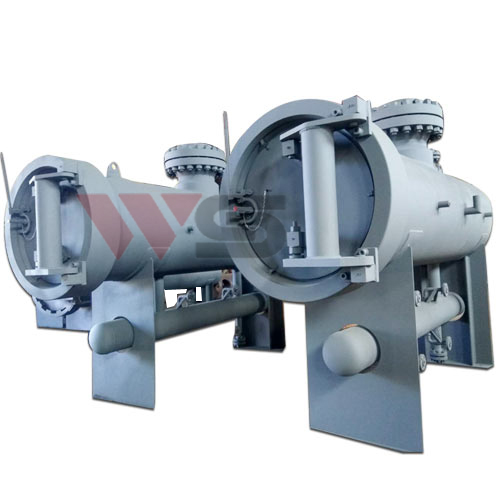

Gas Separator Structure/Pictures

1.Horizontal Type

2.Vertical Type

| 1.Important Tips | |||||

| Quick Opening Closure &Filter Elements | |||||

1.Quick Opening Closure. Separators can be equipped with quick opening closure to facilitate full access to the filter elements for replacing and cleaning. Quick opening closure provides a practical solution with assures safety access to the filter and allows to manage the large size for opening and closing in only one minute. each clsoure is widly tested after manufacturing to give assurance of maximun reliability through time. Quick opening closure is one of the most necessary parts, we can produce various kinds of Quick opening closure according to the different size and pressure. our quick opening closure has acquired the national patent(patent NO.is 03210870.2).normally, opening the closure it always need 2-4 workers to open with pliers at least 5-7 hours. our quick opening closure opens within one minutes, it saves labour and enough time. | |||||

2.Filter Elements. we take high quality filter element and our filter element have following characters

1)filter element has character of natural hydrophobicity which can guarantee the achievement of the absolute filtration requirements under dry and wet conditions. 2)filter Membrane pore structure according with the orifice plate model, low pressure under working condition. 3) strong Negative electrostatic membrane , good anti-pollution performance and long service life. 4)Large filtering area, high gas flux and less energy consumption. 5)good Temperature resistant performance , air impact resistance and can be repeated steam disinfection. 6)Installation direct. Note: when differential pressure value of the pressure gauge reaches 150 kpa we suggest to clean or replace filter element. | |||||

| Material/Specification of Filter Elements | |||||

| Filter Meid:Molded fiberglass bonded with phenolic resin | |||||

| Inner core:carbon steel or S.S. | |||||

| End Cap:Carbon steel or S.S. | |||||

| Gasket:Rubber | |||||

| 2.Features &Benfits of Gas Separator | |||||

| 1 | low pressure drop | ||||

| 2 | Quick opening closure elments easily replaceable | ||||

| 3 | Increase pipeline working Efficiency | ||||

| 4 | convenient for maintance | ||||

| 6.Installation and Maintenance | |||||

After finished the hydrotest its essential to open filter separator ,empty the liquid inside the shell and wipe clean or airing the filter separator innner and sealing parts then paint Glycerine as to lubrication in avoid of the rust. the rust happend can take damage for the equipment and trouble for engineering. | |||||

Our Project Site Pictures

![]()

| Company Information | ||||||||

| Shenyang WenSheng Instrument Equipment Co., Ltd.is the Joint-stock collection of production and scientific research in one . we are the professional manufacturing enterprises of oil and natural gas pipeline (non-standard) equipment more than 15 years. | ||||||||

| we focus on petroleum, natural gas pipeline (non-standard) equipment research, development and production in decade years. We provide our customers in the worldwide with full set of pigging equipment for long distance transferring pipeline;monolithic insulation joint,gas Distribution and filter separation & cyclone separation equipments and the perfect Pre/After Sales services include business consulting, equipment configuration, installation debugging, technical training , spare parts supply and expert guidance etc. | ||||||||

our products are much more perfect with the accumulation of experience and the feedback from customers in the process of the usage of equipment and the improvement of technique after hard technical research and study .The main technical Index and performance have reached to the advanced domestic and international standard. | ||||||||

Our products won several national patents like LSM wheel-paddle Quick Opening Closure (National patent number: zl 2016 2 0079375.6), Band locking Quick Opening Closure (National patent number: zl2016 2 1187766.6),Electric Automatic Quick Opening Closure (National patent number: zl2016 2 1191754.0) the supporting wheel pipeline polyurethane cleaning pig (National patent number: zl2016 2 1189950.4) , and the reducing pipeline cleaning pig (National patent number: zl2016 2 1187652.1).,Pig Signaller removal under pressure(National patent number:zl2016 2 1172897.7) etc. | ||||||||

Our company have got ASME U Certificate( Certificate No.:55405);ISO9001:2000 Certificate; ISO14001:2000 Certificate and ISO OHSAS 18001:2007) etc..... | ||||||||

Contact Information Contact Person: Mrs.Jessica Zhang Sales Email: export@wsyq.com Tel.:+86-4000-627-672 Whatsapp: +86 156 4023 3593 Wechat:+86 156 4023 3593 Skype ID:wsyqgs.jessica@yahoo.com |